Farmers, consumers, and contractors form close relationships in agriculture. Buyers rely on the timely delivery of contracted crops in the agreed quality. Farmers have a vital interest in supplying these crops, and contractors need detailed information on farmers’ fields to optimise their operations. These relationships require a steady flow of accurate information on crop status. Obtaining and sharing this non-standardised information is currently costly for the parties involved because they all face issues in dealing with multiple vendors and platforms across the farming community. So, how do we enable and accelerate the transition to a fair, healthy, and environmentally friendly food system while improving processes along the value chain in agriculture – and more precisely in terms of food?

Ms Intza Balenciaga, project manager at AZO, recently spoke with Mr Paul de Lange, CEO of Calabi; Mr Stefan Scherer, founder and CEO of Geocledian GmbH; Mr Steffen Schmieder, CEO of Hansenhof_electronic Softwareentwicklung; and Mr Niels Baert, founder of Hyler BV. These ATLAS 2021 Open Call winners had the chance to demonstrate how their innovative solutions – Calabi, Transparent Crop Growth (Ag|Knowledge), FDX7, and HEMPDATASHARE – will contribute to the ATLAS Interoperability Network by providing first-class data-driven services to tackle agricultural challenges related to food systems.

- Please give us a sneak peek of your solution: Why is it relevant in agriculture, and how did the idea(s) behind it emerge?

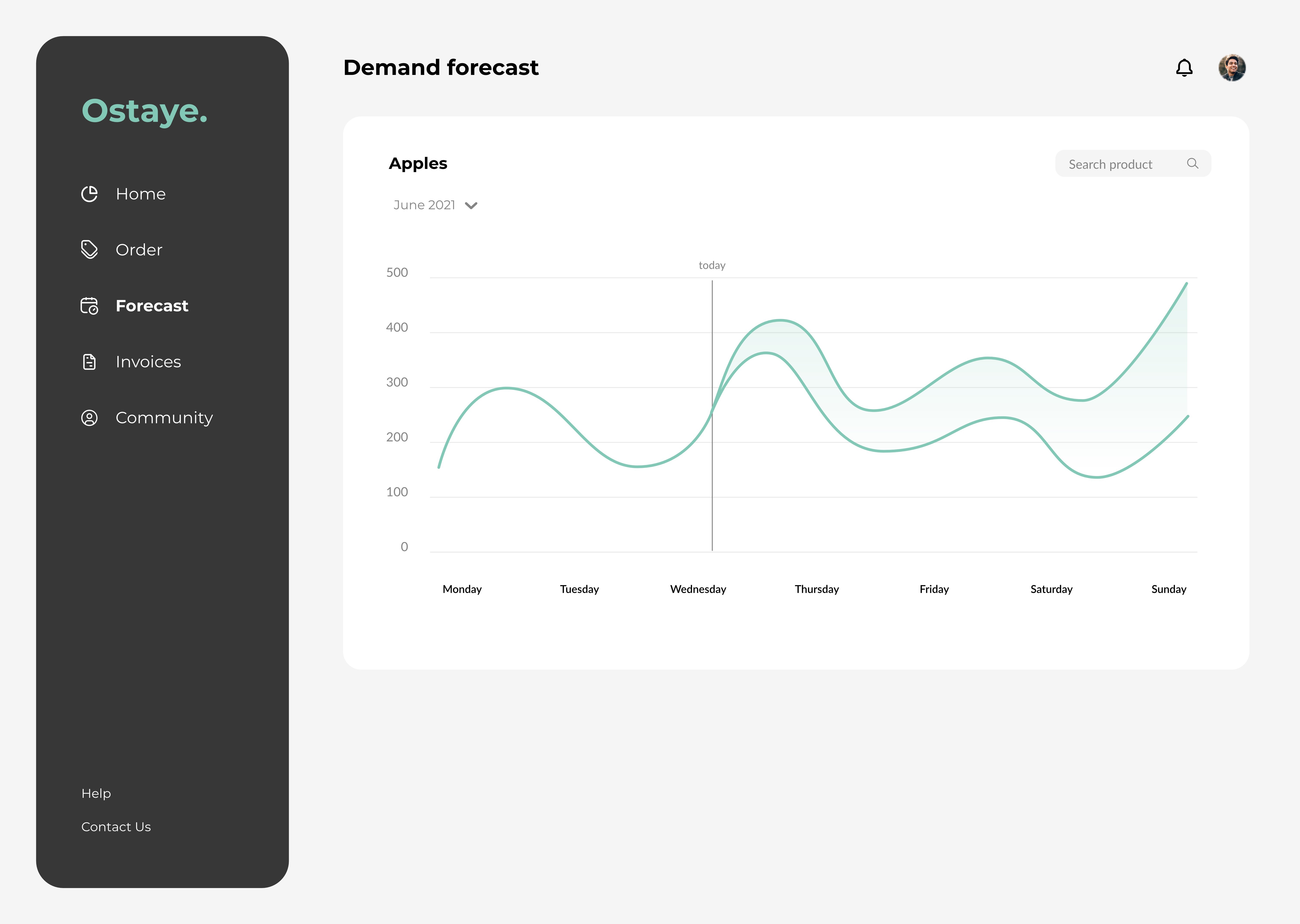

Mr Paul de Lange: Calabi offers a marketplace that empowers local farmers and producers by connecting them directly to a community’s retail sector. It helps provides short supply chain stakeholders with a digital forecasting solution that empowers farmers in making their crop planning and local merchants in their procurement processes. It thereby reduces the stressful sales process so that the farmers can focus on their passion: the product. Our overall objective is to turn the short supply chain into a sustainable and serious alternative to the global value chain. To this end, we empower end users with optimisation services – the type that typically only benefits large enterprises to a significant degree. For ATLAS, Calabi is developing a demand forecasting solution.

Mr Paul de Lange: Calabi offers a marketplace that empowers local farmers and producers by connecting them directly to a community’s retail sector. It helps provides short supply chain stakeholders with a digital forecasting solution that empowers farmers in making their crop planning and local merchants in their procurement processes. It thereby reduces the stressful sales process so that the farmers can focus on their passion: the product. Our overall objective is to turn the short supply chain into a sustainable and serious alternative to the global value chain. To this end, we empower end users with optimisation services – the type that typically only benefits large enterprises to a significant degree. For ATLAS, Calabi is developing a demand forecasting solution.

Mr Stefan Scherer: Our solution, Ag|Knowledge, provides timely, accurate, independent, and standardised crop status information and advisory services across platforms to the benefit of all stakeholders along the supply chain. This includes farmers, buyers, advisors, contractors, and the government. Our harvest maturity service, for example, will make it possible to determine optimum harvest times. All our services build on a unique combination of satellite monitoring, weather monitoring, crop modelling, artificial intelligence, and in-situ measurements. Ag|Knowledge will thus help create transparency in the actual status of primary production throughout the supply chain, and ATLAS will play a decisive role in providing interoperability among all systems and sensors.

Based on this transparency, we aim to simplify and improve the processes along the agriculture value chain. This will help connect farmers to food producers, advisors, contractors, administrative bodies, and other industry players to improve the primary production, better manage supply chain risks, and increase efficiency and traceability – and thus sustainability. Farmers will have a better overview of their actual crop performance and be able to plan the right measures. Buyers, meanwhile, will be able to tailor their advisory services to farmers much more efficiently. Obtaining near-real-time status information on all their contracted fields will enable them to avoid costly field campaigns and having to rely on farmers to collect standardised in a timely fashion. Through ATLAS, contractors will be able to use data to better plan their harvest activities while improving yield quality (and thus revenues). Finally, Ag|Knowledge will make it possible to provide governments with information that documents the fulfilment of obligations related to subsidy schemes.

Based on this transparency, we aim to simplify and improve the processes along the agriculture value chain. This will help connect farmers to food producers, advisors, contractors, administrative bodies, and other industry players to improve the primary production, better manage supply chain risks, and increase efficiency and traceability – and thus sustainability. Farmers will have a better overview of their actual crop performance and be able to plan the right measures. Buyers, meanwhile, will be able to tailor their advisory services to farmers much more efficiently. Obtaining near-real-time status information on all their contracted fields will enable them to avoid costly field campaigns and having to rely on farmers to collect standardised in a timely fashion. Through ATLAS, contractors will be able to use data to better plan their harvest activities while improving yield quality (and thus revenues). Finally, Ag|Knowledge will make it possible to provide governments with information that documents the fulfilment of obligations related to subsidy schemes.

Mr Steffen Schmieder: FDX7 is a software module that enables consumers to track the production chain of food from cultivation to the finished retail product. The consumer can easily check the production chain and the quality standards being met by simply scanning a QR code on the product packaging.

Nowadays it is imperative that we as a society make sure that we consume sustainable (and regional) products whenever possible in our everyday lives. In many cases in the food industry, it is possible to see the properties of a product based on symbols and descriptions on the packaging. However, it is usually unclear to the consumer where and under what conditions a product was manufactured, particularly because the origin of the raw materials of many foods was not even recorded, let alone noted on the packaging. And how sustainable is an organic lemonade if the lemons are being shipped from Africa and the sweeteners are imported from the United States, and the required water from France has to be transported across the Alps?

Nowadays it is imperative that we as a society make sure that we consume sustainable (and regional) products whenever possible in our everyday lives. In many cases in the food industry, it is possible to see the properties of a product based on symbols and descriptions on the packaging. However, it is usually unclear to the consumer where and under what conditions a product was manufactured, particularly because the origin of the raw materials of many foods was not even recorded, let alone noted on the packaging. And how sustainable is an organic lemonade if the lemons are being shipped from Africa and the sweeteners are imported from the United States, and the required water from France has to be transported across the Alps?

If manufacturers rely on regional ingredients and pay attention to quality, they should be rewarded. The best way to do this is through consumers’ purchasing decisions, but consumers are currently not provided with the necessary information. This is exactly where we want to intervene with FDX7.

Mr Niels Baert: Through our solution, Hyler is active in a niche sector where new machinery is being developed to help push the uptake of new fibre crops (like flax, hemp, and miscanthus) to deal with many of the challenges outlined in the European Green Deal. Our new HEMPDATASHARE machine is designed to automatically facilitate data collection and sharing among all the stakeholders involved in these niche crops in a greenfield approach. We want to use the standardisation and principles offered by the ATLAS project as a strong base to start from in this sector, where data sharing will enable the development of new features and services.

Mr Niels Baert: Through our solution, Hyler is active in a niche sector where new machinery is being developed to help push the uptake of new fibre crops (like flax, hemp, and miscanthus) to deal with many of the challenges outlined in the European Green Deal. Our new HEMPDATASHARE machine is designed to automatically facilitate data collection and sharing among all the stakeholders involved in these niche crops in a greenfield approach. We want to use the standardisation and principles offered by the ATLAS project as a strong base to start from in this sector, where data sharing will enable the development of new features and services.

- What has been your company’s and/or solution’s biggest challenge thus far?

Mr Paul de Lange: It’s been in actually delivering a solution that focuses on adding value for the client. Many of the farmers and clients we offer services to are not digitally apt, and it’s sometimes difficult to figure out what digital services can boost their processes in the most meaningful way.

Mr Stefan Scherer: When we started Geocledian in 2013, digital agriculture was just about to emerge, and Sentinel-2 had not been launched yet. The market and digital infrastructure were not yet mature, and data wasn’t reliably available. This made it difficult for us to position our idea and product in the market. Now the situation has largely changed. Digitalisation is a clear must and the emergence of new sustainability regulations like the EU taxonomy law and other climate protection measures support data exchange and transparency. Plus, ATLAS is now helping us solve the connectivity problem.

Mr Steffen Schmieder: The biggest hurdle that we keep having to overcome is the fact that there is a large number of processes in agricultural practice that do not record data autonomously and that machines and devices from different manufacturers often use different documentation solutions with proprietary data channels and formats. This makes it much more difficult to map a process chain completely and seamlessly in software. Meanwhile, having data that is as complete as possible is one of the most important prerequisites of offering smart farming applications. A network like ATLAS can show important and innovative ways to solve these problems.

Mr Niels Baert: The use and benefits of data sharing are not well known in niche agricultural sectors, which is why we aim to spread the word. In the past, data ownership is a topic that has been used to prevent data sharing systems.

- What opportunities will ATLAS offer your solution and/or company? How will this interoperability network help you develop and nurture your business case?

Mr Paul de Lange: Interoperability is one of the most important aspects of our solution. We really want to make a large impact not just on our short supply chain clients, but on the entire concept of the short supply chain. ATLAS really challenges us to focus on making our solutions reusable and interoperable.

Mr Stefan Scherer: Ag|Knowledge has been set up as middleware that is designed for integration into proprietary farm management systems (FMS). ATLAS is now helping us enlarge our business model in two ways: Instead of connecting to a single FMS, we can facilitate the exchange of information across platforms and thus better connect the stakeholders along the value chain. Furthermore, it’s becoming easier for us to connect directly to in-situ data providers like harvest machinery, weather data, and IoT sensors. This will significantly help us improve our services.

Mr Steffen Schmieder: In order to use resources sparingly and sustainably in agriculture, a high level of detail in the collection of data is required. This cannot be done manually in manufacturing processes, which is why autonomous documentation systems must be used. There are already many possibilities for documentation. In agriculture, machines are equipped with job computers that evaluate soil samples, fertiliser spreaders intelligently regulate their application rate, and farmers use artificial intelligence to detect plant pests and diseases at an early stage. Logistics chains have long been able to provide information at any time as to which goods have been transported from one location to another. Nowadays, there is no lack of the necessary data in many places, but it is accumulated in isolated solutions in different places for different purposes. For a long time, it was difficult (if not impossible) to link this data while maintaining an overview of the whole process up to the finished product.

Up-and-coming solutions like ATLAS make it possible to combine manufacturer-independent data from different sources for a variety of purposes and to generate new information and instructions from the resulting added value. You could say that ATLAS is a way to connect all the individual, isolated solutions that I just mentioned.

Since the real-world practices and environment involved in our project usually do not provide us with a holistic and complete set of data, we often have to intervene with many different interfaces, implementation languages, and data formats. Thanks to ATLAS, we can exchange, combine, and utilise existing data sources more quickly and easily.

Mr Niels Baert: ATLAS will deliver the principles and methods that will enable data sharing and guarantee proper, open, and transparent API development. The ATLAS network will assure data sharing in a safe manner.

- What was/were the main reason(s) why you decided to participate in the ATLAS Open Call 2021?

Mr Paul de Lange: The explicit challenge of making our solution work across multiple regions was very appealing. We were also impressed with the scope of the ATLAS network in terms of both depth and width.

Mr Stefan Scherer: We decided to participate in the ATLAS Open Call because we wanted to become part of the ATLAS community at an early stage. We consider ATLAS a very promising venture that addresses one of the key problems of digital agriculture. Being one of the early adopters will give us an advantage in the market.

Mr Steffen Schmieder: The ATLAS network is not trying to create an isolated proprietary solution for the market. It wants to give farmers and agricultural technology manufacturers the opportunity to continue using their existing solutions with the possibility of exchanging data with each other.

Such an overarching solution is entirely in our interest. In the long term, it also represents real added value for our customers, and ultimately for our society.

Mr Niels Baert: The aim is to become part of a bigger digital farming family whose members help each other for the purposes of this project and the longer term. This project represents Hyler’s first step in the space of smart farming. Sharing information and having open discussions with the entire ATLAS consortium is key to our future development.

- Finally, let’s take a quick look into the crystal ball: What’s going to happen with your company and/or solution in the future?

Mr Paul de Lange: In the next five years, we will be boosting the short supply chain in more than five European regions. About 10 years from now, we hope the short supply chain will be a sustainable and macroscopic alternative to the global value chain, and that our platform will be part of this transition.

Mr Stefan Scherer: Within the next five years, we want to become one of the most recognised agricultural platforms in Europe for transparent, high-quality information based on satellite and weather data. We also want to support the global transition to sustainable agriculture. The EU is one of the key drivers of this transition. Moreover, in a globalised supply chain, we consider the ESG (environmental, social and governance) principles applied in agriculture as key to improving the livelihoods of hundreds of millions of smallholder farmers in developing countries. This is what drives us.

Mr Stefan Scherer: In our project, we use data collected from the production of malting barley to the bottling of brewed beer to give the customer a choice. We offer them the chance to choose a product that has been grown and produced in their home country and region. That is more sustainable than the alternative. When buying a product, customers can see that they aren’t just spending their money on a bottle of beer, but also supporting their fellow citizens in the region and making a real contribution to environmental protection. Since we firmly believe that everyone is capable of making the responsible choice when given the necessary information, we think this is an important step in the right direction.

Thinking about the future of this solution, it is obvious that it will not stop with malting barley. Much of the experience we have gained in this first use case can also be transferred to other, similar use cases for other products and raw materials. In other words, there is still a lot of potential for the future and further development of FDX7.

Mr Niels Baert: We are currently in a scale-up phase in which we are hoping to become one of the leading machine construction companies in some of the emerging niche sectors in the agricultural domain. Hyler is helping these sectors evolve and become economically stable.

Did you enjoy this interview? Anyone interested in these innovative solutions can obtain key insights at the ATLAS Demo Day 2022 on 23 November (save the date!) or get in touch with these innovators via email at paul@calabi.be, stefan.scherer@geocledian.com, info@hansenhof.de and/or niels@hyler.be. Meanwhile, stay tuned for more upcoming interviews with the ATLAS 2021 Open Call winners via the ATLAS mailing list or AZO’s blog!

Comments are closed.